image001

Town of Westport, CT

image002

Town of Plymouth, CT

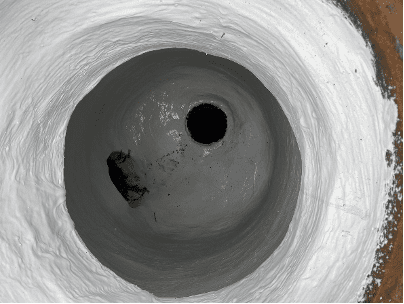

Both of these manholes and a few more were recently rehabilitated by Green Mountain Pipeline Services, LLC (GMPS). The one on the left is from the Town of Westport, CT and the one on the right is from the Town of Plymouth, CT. Both projects involved precast manholes that were located immediately after the discharge of force mains. The end of force mains are particularly vulnerable locations for concrete structures. When the flow from the force main enters the manhole, the H2S gas is released. As can be seen in the photos above, over time the corrosion in a manhole can be significant, creating unsafe conditions. Hydrogen sulfide (H2S) is often a colorless gas with a rotten egg odor, which is commonly referred to as “sewer gas”. H2S is highly poisonous and highly corrosive in wastewater applications. The various problems associated with hydrogen sulfide generation are its toxicity, noxious odors, and the generation of corrosive sulfuric acid. When sewage becomes stagnant, such as when a pump station at night does not pump for hours at a time, H2S gas can be generated in the anaerobic conditions in the wet well and force main.

The Town of Westport had three manholes at the end of a 12-inch 2-mile-long force main that were severely deteriorated from hydrogen sulfide. The force main discharge manhole was particularly difficult to access since the force main entered the manhole from the bottom. The Town went to the expense to install a bypass connection in the force main thirty feet before the discharge manhole to allow the flows entering the structure to be bypassed. What is interesting is that these manholes were only six to eight years old and were epoxy coated from the manufacturer. It was not known at the time of that initial coating that the joints in the manholes should have been filled in with a cementitious material and then epoxy coated to ensure the manhole epoxy coating was monolithic throughout the structure with no pin holes.

The Westport manholes were rehabilitated using a composite system that Green Mount Pipeline Services has had tremendous success with for over 20 years. The manholes were first pressure washed, and after being properly prepared, one to two inches of Strong Seal MS-2C was applied and troweled to ensure a good mechanical bond with the original structure. After the troweling was completed, the surface was lightly brushed to create a textured surface which, in turn, increases the surface area of the applied MS-2C. This process also creates the opportunity for a mechanical bond between the cementitious liner and the epoxy. After the MS-2C was cured, the GMPS crew applied 125 mils of Parson’s Parsonpoxy SEL-80.

The Town of Plymouth, CT manholes were also suffering from severe H2S corrosion. These manholes were also located immediately downstream of a 10-inch force main discharge. Three manholes received a ½” to 1” coating of Strong Seal’s MS-2A and 125 mils of Parson’s Parsonpoxy SEL-80.

Below are just two photographs showing the completed manholes.

image003

Town of Westport, CT

image005

Town of Plymouth, CT

Note in the photo on the left the flows were bypassed and the force main discharge connection can be seen at the bottom of the manhole. On the right is the Plymouth CT discharge manhole and the force main enters the structure at the 12:00 position. Green Mountain Pipeline Services has extensive experience in manhole and wet well rehabilitation. GMPS has used the Strong MS-2A and Parsonpoxy SEL80 for over 20 years experiencing significant success with this system. Because of this significant experience and success, GMPS can offer the best rehabilitation solutions for your underground structure deterioration issues.

MORE ABOUT GREEN MOUNTAIN PIPELINE SERVICES

Founded in 2003, and acquired by Infrastructure Services Group LLC in 2018, Green Mountain Pipeline Services LLC offers a wide range of pipeline inspection and rehabilitation services using trenchless technology. This includes closed circuit TV inspection of mainlines and laterals; cured-in-place pipe (CIPP) mainline and lateral lining, plus trenchless spot repairs; grouting of mainlines, manholes and laterals; manhole rehabilitation; manhole/structure cementitious lining and reconstruction, with epoxy coating for corrosion control as needed; pipeline/structure cleaning and vacuuming; and smoke testing, manhole inspections, dye testing and flow isolation.

Headquartered at 768 South Main Street, Unit 1, in Bethel, Vermont, GMPS is a subsidiary of Infrastructure Services Group LLC which acquires, funds and manages profitable and well-positioned private companies that specialize in water and wastewater pipeline and manhole inspection, maintenance and rehabilitation.