Norfolk Sewer District, Norfolk, CT – Sanitary Sewer Collection System Rehabilitation Project

Project No. 058-001

The town of Norfolk, located in Litchfield County, Connecticut is in the northwest corner of the state and borders Massachusetts to the north. Situated in the foothills of the Berkshires, Norfolk was settled in 1744 and incorporated in 1758. Originally a farming community, the town saw a rise in industry in the 19th century as small factories built along its numerous streams produced tools and farm implements from locally mined iron ore. By the late 19th century Norfolk became a resort community, and visitors from Connecticut, New York, and Massachusetts flocked to the small town during the summer. Today, Norfolk retains its rural character and is home to three state parks, miles of hiking trails, and the Yale Summer School of Music and Art.

The Norfolk Sewer District was established in 1898 and is a self-governing taxing district that covers those properties connected to or maintained by the Sewer Commission. Its plant, located at 259 Greenwoods Road West, treats domestic wastewater generated within the district and discharges it to the Blackberry River. Most of the gravity pipelines and manholes were installed around 1900 making the system over 120 years old. The system consists of approximately 50,000 ft. of sanitary sewer and 225 manholes. Clay tile pipe compromises about 85% of the system. AC pipe is the remaining 15%. There is not a single pumping station on the system, all sewage flows to the wastewater treatment plant by gravity.

The current wastewater treatment plant was built over 50 years ago in 1970, and the system consists of mostly residential customers with very few businesses. Originally it was a large tank with sand filter beds which are still in use today. The average daily flow (ADF) at the treatment plant is 500,000 gallons per day (gpd). During a rain event the flows can reach 1,000,000 gpd. During the dryer summer months flows average 70,000 to 90,000 gpd. The increase in flows due to rain events and infiltration show the real need to rehabilitate the collection system.

In April of 2020 during the height of the pandemic, Green Mountain Pipeline Services (“GMPS”) bid on the project in Norfolk, CT and was the low bidder on the $3.8-million project. The project consisted of cleaning, TV inspection of 35,870 feet of pipe, cured in place lining of 35,870 feet of 6” to 12” sanitary sewer line. Also included was removal of protruding lateral connections, bypass pumping, reconstruction of some sewer sections and 1,000 vertical feet of sanitary manhole rehabilitation.

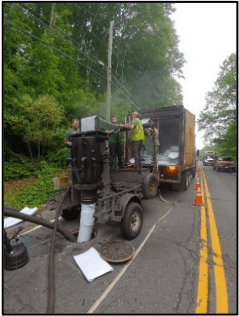

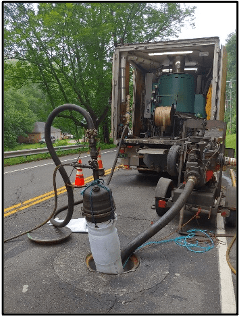

In the photos below, GMPS is setup on a State of Connecticut road on a 343 ft. section of 12- inch sanitary sewer to be lined that is not far from the wastewater treatment plant. The footprint for the equipment is fairly long as can be seen in the first photo. The second through fourth photos show the liner being prepared for insertion, actual inverting of the liner, and then applying steam to cure the liner.

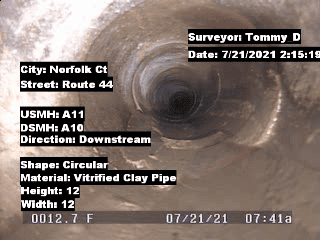

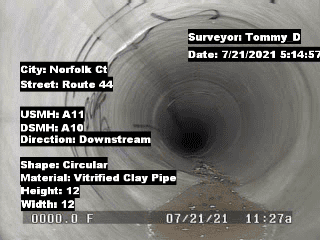

The above process is completed on a daily basis on this project. Below you can see the before and after results. The pipe on the left is a 100-year-old 12-inch vitrified clay pipe and on the right is the same line after lining with a new 50-year design life structural CIPP liner.

As stated above project consisted of over 1,000 vertical feet of manhole rehabilitation. This consisted of stopping all active infiltration which was considerable with a lot of heavy rain over the duration of the project. The infiltration was stopped with American Chemical Grout Co.’s ACG-MBA acrylamide grout pre-mix.

With the age of the manholes being over 100 years, all of the manholes were brick, block, or a combination of both as you can see in this photo. This manhole was rehabilitated after the 8” sewer line had a cured-in-place liner installed. This helps to create a monolithic liner in the manhole right up to the cured-in-place liner. After all infiltration was stopped, the walls were prepared with high pressure water blasting. Notice in the photo the high probability of rainfall induced infiltration at the top of the structure. The block area of the manhole in the chimney has open areas between each block which would allow infiltration during a rain event.

Any large voids would be filled in with Strong’s QSR product. It should be noted that proper preparation of the manhole surface prior to rehabilitation is one of the most critical parts of the process. There is no perfect coating or lining system that will work unless the surface of the manhole is prepared with painstaking care. Proper preparation of the manhole walls is key to a successful project and ensures the lining will last many decades.

The cementitious lining on the walls consisted of ½” of Strong’s MS-2A cementitious material. The compressive strength per ASTM C109 for MS-2A is >9,000 psi. The flexural strength per ASTM C293 is >1,600 psi.

GMPS has been applying The Strong Company’s MS-2A product in the New England area for over 25 years with great success!

Here is the manhole after completion. Note the lining was applied from the frame at the top of the manhole, down the manhole walls and included the bench right up to the CIPP liner. Every effort is made to bring the cementitious liner right up to the cured-in-place liner to create a monolithic structure.

Results

The project was completed well under budget. The Wastewater Treatment plant has seen a significant drop in flows after the collection system rehabilitation. The spring of 2021 was a very wet spring. From July 1st to July 22nd the Town of Norfolk recorded over twelve inches of rain. As stated earlier the average daily flow (ADF) at the treatment plant has been 400,000 gallons per day (gpd). During a rain event the flows can reach one million gpd. During the dryer summer months flows drop to 70,000 to 90,000 gpd. In 2019 the plant processed 141,880,000 gallons. In 2020 the annual flows dropped to 102,770,000 gallons and in 2021 they dropped even further to 98,500,000 gallons per year, a 30% drop in total flow! The sanitary sewer rehabilitation project is showing a significant improvement in the elimination of infiltration in the areas that were rehabilitated. The work was performed for the Town of Norfolk Sewer Department with engineering services provided by WMC.

MORE ABOUT GREEN MOUNTAIN PIPELINE SERVICES

Founded in 2003, Green Mountain Pipeline Services offers a wide range of pipeline inspection and rehabilitation services using trenchless technology. This includes closed circuit TV inspection of mainlines and laterals; cured-in-place pipe (CIPP) mainline and lateral lining; trenchless spot repairs; grouting of mainlines, manholes and laterals; manhole/structure cementitious lining and reconstruction, with epoxy as needed; pipeline/structure cleaning and vacuuming; and smoke testing, manhole inspections, dye testing and flow isolation.

Headquartered at 768 South Main Street, Unit 1, in Bethel, Vermont, GMPS is a subsidiary of Infrastructure Services Group LLC, which acquires and funds profitable and well-positioned private companies that specialize in water and wastewater pipeline and manhole inspection, maintenance and rehabilitation.