City of Stamford, CT contracts with Green Mountain Pipeline Services to employ trenchless technology to repair a single length of pipe that all other firms contacted said “it couldn’t be done”.

Stamford, CT

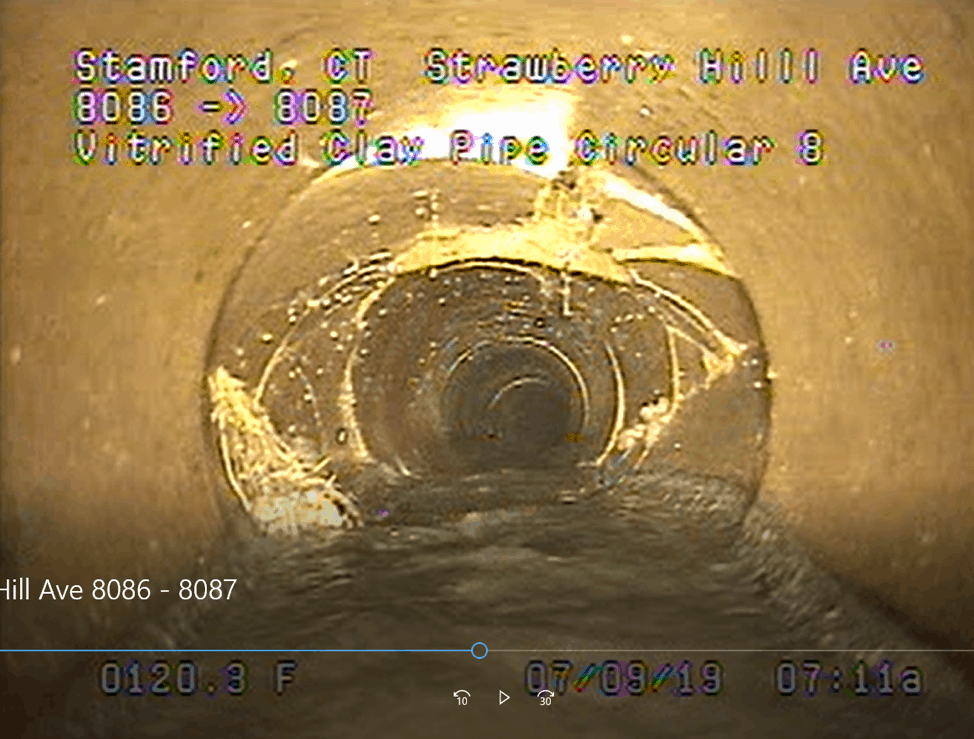

The City of Stamford had a problem. There was an 8-inch sanitary sewer located in a sidewalk on a very busy street, Strawberry Hill Ave. At the downstream end of the line was a water main and a four-foot-high stone wall. The issue was the 8-inch line of vitrified clay pipe had areas with multiple cracks and roots. The downstream end of the line had no access point or manhole. The 8-inch line connected with a lateral line from a building via a tee connection, which then flowed out to a manhole in the middle of the busy street. This made any type of rehabilitation extremely difficult. How can the cracked sewer pipe be lined without access to the downstream end via a manhole?

The City contacted several contractors who all said the installation of a manhole at the downstream end was necessary. This would have been extremely costly with a stone wall next to the line that would need to be taken down and rebuilt, a water line was right next to the pipe, the pipe was in front of a school and the sewer line was 14 to 15 feet deep in the side walk of a busy street.

Green Mountain Pipeline Services (GMPS) were the only ones who could do the job without such a costly excavation. GMPS had an initial plan of attack and intended to work hand in hand with a specialty contractor to install a liner via a “blind shot”. For various reasons this approach failed. GMPS needed an alternative and reached out to Formadrain, a trenchless spot repair process GMPS have been using for almost three decades. GMPS new approach was to install three 80+ foot liners one after the other. Each successive liner would overlap the previous liner, which would enable us to line the entire length of pipe.

GMPS contacted Carl at Formadrain and a solution to this particular project was formulated. In the end we ordered three 80+ feet of pre-impregnated sections of Formadrain’s revolutionary Durapox liner.

The properties of the fiberglass and epoxy composite liner exceed minimal design criteria within ASTM F1216 standard for CIPP lining by a factor of 5, making it a thin but extremely tough liner when designed according to the referenced standard. The steam-cured latent resin was specifically formulated to not cure without sunlight or heat for 60 days. This allowed Formadrain to pre-impregnate the liners in their shop, in a controlled environment and ship them to GMPS without fear of the liner hardening on its own, all without the use of a reefer truck.

Installing the three 80+ foot sections of liner was not easy. We had to estimate the distance from the tee to the manhole in the street. We then had to design a pulling device that would allow us to work through the tee without digging into the tee and the pipe. Once the plan was in place the three pre-impregnated sections had to be ordered, built in Formadrain’s facilities, get through customs from Canada and due to scheduling be stored at GMPS’s facility in Vermont all without kicking off and curing.

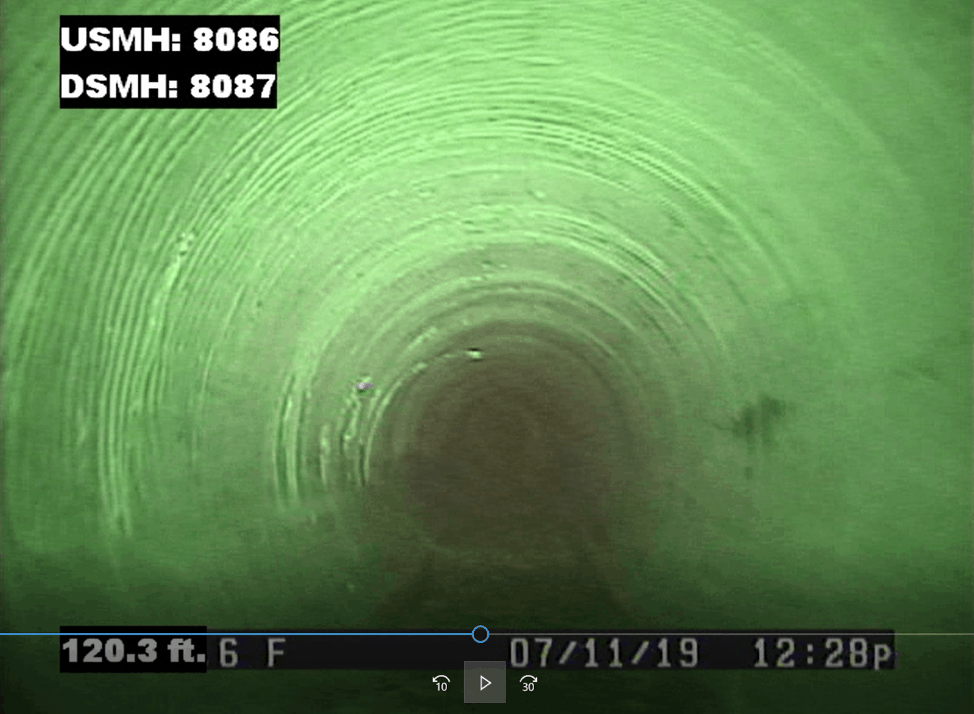

Once onsite the flow in the sewer needed to be bypassed. Fortunately for Green Mountain Pipeline Services they perform most of their own bypass with their own equipment and crews. Once the flow was bypassed the line was inspected one final time. The line was ready, and the liners were ready to install.

Installing 80+ feet of 8-inch pre-impregnated liner was not easy. The liner was heavy. GMPS had to deal with getting the liner in the hole, complete the bend down in the manhole and pull the liner in blind from the manhole in the street all the while everything was being pulled through via the tee connection. Once each liner was installed steam was applied and each liner was cured in approximately 90 minutes.

In the end the liner was perfect and the entire line from end to end was lined. Due to working blind and a fitting on the end of the liner we stopped about a foot before the tee connection. The field work took 2 ½ days to complete even with the challenging nature of the project. Excavating and building the new manhole would have taken weeks of work and been extremely expensive.

MORE ABOUT GREEN MOUNTAIN PIPELINE SERVICES

Founded in 2003, Green Mountain Pipeline Services offers a wide range of pipeline inspection and rehabilitation services using trenchless technology. This includes closed circuit TV inspection of mainlines and laterals; cured-in-place pipe (CIPP) mainline and lateral lining, plus trenchless spot repairs; grouting of mainlines, manholes and laterals; manhole/structure cementitious lining and reconstruction, with epoxy as needed; pipeline/structure cleaning and vacuuming; and smoke testing, manhole inspections, dye testing and flow isolation.

Headquartered at 768 South Main Street, Unit 1, in Bethel, Vermont, GMPS is a subsidiary of Infrastructure Services Group LLC, which acquires and funds profitable and well-positioned private companies that specialize in water and wastewater pipeline and manhole inspection, maintenance and rehabilitation.